We at Absolute Steel are dedicated to constant improvement and we are proud of our frame system. Please take a moment to understand the technical aspects of our building systems. Note that information and pictures of similar products made by other companies are furnished only for comparative evaluation.

Absolute Steel quality is undeniable. Our steel buildings have held up to the extreme conditions of Hurricane Katrina and sustained winds of over 140 MPH. They have survived rust-free deep within salt mines of Cargill, were unfazed by the rugged terrain of Afghanistan and still stand tall in the freezing Alaska tundra.

Absolute Steel’s warranty is the best in the industry.

We are so confident in our structures that our frame systems have a 20 YEAR WARRANTY and the exterior panels, depending upon which panel you purchase, have a 20 to 40 year warranty against fading, chalking, or peeling.

Maximum Rust and Corrosion Resistance

There is a good reason our structures are requested by all branches of the US Armed Forces.There is a good reason why our structures were the choice for the high-corrosion environment of Cargill’s Ohio salt mines.

Our Buildings are Tested Under the Toughest Conditions

United States Army

United States Marines

United States Navy

United States

Border Patrol

Dept. of Homeland Security

Our steel frames are manufactured with 2″ x 4″, 2″ x 3″, and 2″ x 2″ 14-gauge and 15-gauge steel tube.

Below are representative specifications of our frame system:

- Base Rails and Side Walls: 55-65,000 psi minimum yield strength.

- Peaks and Eaves: 55-65,000 psi minimum yield strength.

- All components receive a galvanized protective layer that exceeds industry standards. (G90 rather than G60). As a final measure this extra-strong layer receives a patented clear coating for unsurpassed corrosion protection.

Yield strength – If you would like to know what this is and why it’s important, read “Yield Strength – How it Applies to Steel Construction“.

Component Engineering and Manufacture

Let’s look at how our components are made, and why.

Base Rail System: A better foundation.

The base of any structure is one of its most critical components. It is literally the foundation of the structure’s strength.

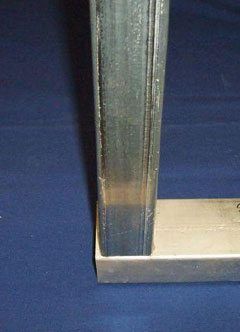

This is why Absolute Steel uses an “insert system” in all its base components. None of the base’s critical parts, which bear the structure’s weight, have been subjected to crushing, rolling or bending, as practiced by other manufacturers. See the images below for examples.

Instead of steel tube that’s been stressed, fractured and compromised, you get thicker, unstressed steel tube whose inserts overlap their accompanying wall supports by a full six inches.

Absolute Steel’s Insert System method requires more time and engineering on our end, but the benefits are worth the effort. In addition to being stronger, benefits include:

- At the lowest points, where water or condensation can collect, you have thick and uniform connections that are much better than swedged* inserts with thinned, stressed walls. (*Swedged = made narrower by crushing or rolling as seen below.)

- 6” vertical inserts of uncompromised steel give you more room and greater strength for wall-height adjustment, when dealing with site irregularities. This means that by default, our frame base rails are built to support varying heights and loads of a structure.

- You always get a smooth and easy fit. You will never need a sledgehammer to pound parts together.

The Worst Connection

(Crushed and bent)

A Better Connection

(But still uses stressed metal)

The BEST Connection -Ours

(No bends = uncompromised strength)

Side-Wall Framing:

One-piece sidewalls make for easier assembly and stronger walls.

Have you ever put up a tent that uses metal poles? You may recall that in most cases the sidewall is comprised of 3 to 4 poles that slip together. They were manufactured this way to make the kit easier to pack and transport, but do you recall how wobbly these tents always were? This type of mulch-piece construction makes for very unstable sidewalls with numerous stress points.

You know that a wall pieced together from several separate parts is not going to be as strong as a single, solid piece of steel. A tent doesn’t need to have strong sidewalls, but a metal structure certainly does.

It is for this reason that we go the extra mile and manufacture single-piece walls that run all the way from base to side wall bends.

This means:

- Your structure boasts a stronger finished wall.

- There are fewer parts to manufacture, and fewer parts for you to assemble.

- You get straight walls every time, with easy height adjustments if needed.

Below is an image of an insert system that uses height extensions (extra, inserted components) for different desired wall heights – and a shot of our one-piece system.

Their Mulch-Piece Sidewall

It stands to reason that with more parts and connections, you get less overall strength. Not to mention the extra work involved!

Our Single-Piece Sidewall

This is ours. No additional parts to mess with, no extra connections to make. A single steel stud that runs from the ground to the eaves. Result: A simpler, stronger sidewall that goes up faster!

Eave Bends and Roof Framing:

The beauty of the Power Bend

For best efficiency and strength, our roof frames include precision-formed bends at the roof’s peak, and at the eaves on each side. In manufacturing these critical parts, we use the highest-strength steel, and a high-tech forming process to provide maximum durability.

The strongest and most efficient way to turn the corner at your building’s roof peak and eaves is to carefully curve the steel frame. But if these bends aren’t well engineered and executed, they can weaken the frame, right at its most critical points.

We’ve solved this in two important ways.

- First, our peak and eave bend components are made from top-grade US steel.

- Second, we use a curving process that is unsurpassed for uniformity and strength.

There is a reason we do this. You probably know why modern automobile bodies are designed to have some curves and angles. It’s the same reason an L- shaped piece of metal (angle iron) is stronger than a straight piece. Those curves and angles add strength to the metal.

There are several different techniques that can be used to make bends for peaks and eaves. One is crushing, which weakens the bend at the point of curvature. Another is rolling the bends into straight steel.

A rolled bend is vastly superior to a crushed bend (we won’t even discuss crushed bends further – they can actually be dangerous yet they are sold even today) but some rolling methods are definitely better than others.

Any rolling process stretches the steel, and makes it thinner. However, we use a special rolling technique that produces what is known as a Power Bend. The resulting curve has had strength added to compensate for the strength that’s been unavoidably taken away. In fact, our Power Bend adds six more surfaces to the original steel tube, with condensed angles and curves that strengthen peak and eave bends where they need it most.

It is this attention to detail and relentless engineering that separates an Absolute Steel building frame from the competition.

To illustrate, here are some typical bends made with the mandrel bend process used by many manufacturers:

Users of this system brag about a “smooth mandrel bend for a cleaner look and a stronger bend transition.” Sounds nice, but there are problems here. Look at the stress lines in the steel, along those curves. You know what’s happened: the steel has been stretched in the rolling process. It’s thinner and weaker than it originally was.

Now here’s the Power Bend:

The Power Bend is accomplished by rolling over the excess steel (not just stretching it out into the part) at the same time that the curvature is created. The resulting rolled edges enhance integrity and strength.

Questions?

Please call us toll-free at 1-877-833-3237

with any questions or quote needs! We are here to help.

Customer service and pricing available from 8:00 am to 5:00 pm Arizona time Monday – Friday.